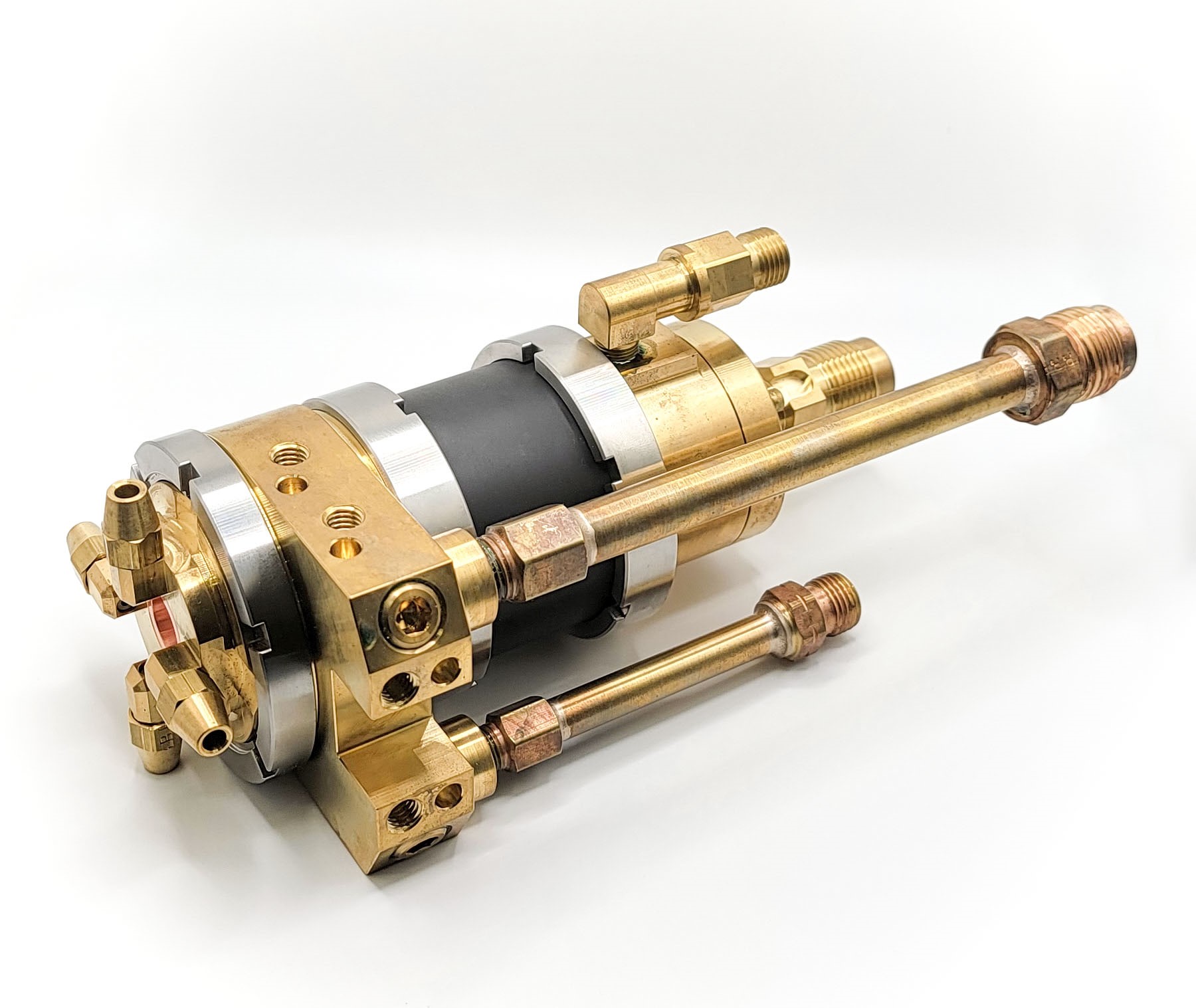

The modular design of the Multus system utilizes mass flow controllers for ultimate repeatability, consistency and easy serviceability. Operator interface is through an intuitive and robust industrial touch screen designed for years of trouble free operation. Recipes can be quickly established and stored for later retrieval. Incorporated into Multus controls are warning and alarm levels for all parameters. We proudly use elmatech plasma power supplies.

What differentiates plasma systems?

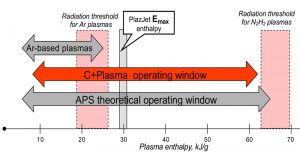

Enthalpy. It isn’t discussed much because plasma torches up to now, legacy, and existing cascade, have inherent design constraints that limit reliable enthalpy operation beyond ~30kJ/g. The Model 5 is rated at about 60kJ/g, at least double the existing “standard”. This high level is achieved at modest power levels (≅ 100kW) – eliminating the need for large gas volumes or high power ratings. This level of efficiency translates to more material deposition on parts in less time and with less cost.

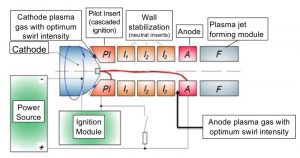

In the cascade design, neutral segments force the arc to “cascade” from the cathode/electrode to anode/nozzle, thereby constraining its length and eliminating instability and drift. This translates to higher deposition efficiencies, improved quality and more consistent coatings. The longer arc length also creates higher voltage which affords lower amperage to achieve desired power levels – which improves hardware durability. Furthermore, the C+ Plasma torch provides greater flexibility in nozzle design, including low and high velocity hardware to efficiently spray different coatings. This amazing feature combines the best of both worlds because the Multus single spray system can apply both high quality ceramic and metallic coatings. Changing the nozzle is all that is needed to convert torch performance between high and low velocity.

Another unique feature utilized by the C+ torch is the double swirl stabilization created by the separate anode and cathode gas design philosophy. Injecting anode gases after the neutrodes vastly improves the efficiency of N2-H2 and Ar-H2 based plasma regimes that require high H2 content to deposit desirable coatings. This contributes to the much improved hardware life.

Plasma gases can be any combination desired. Switching between N2-based and Ar-based plasmas just needs a change of two neutrodes in the torch. Thus, plasma gases can be any combination desired, N2, N2-H2, N2-He, Ar, Ar-H2, Ar-N2-H2, Ar-He, etc.

Due to the durable nature of the torch design, part life is vastly improved. Expected anode life of ~50 hours @ 100kW for N2-H2 plasma and 150-200 hours for cathode and neutral inserts is normal. Using argon or less aggressive gases results in even longer part life.

Arzell, Inc. is renowned for decades of thermal spray integration and automation. The Multus system is no different and utilizes this experience as it is designed for integration into automated or manual systems. Arzell, Inc. also offers turn-key solutions including booths, dust collection systems, robotics, rotating devices, positioners, chillers, integration, powder feeders, cranes, blast systems, laser cladding systems, strip systems, polishing equipment, installation, training, maintenance and calibration.

Connection Requirements

| Electrical | 120/220VAC, 50/60Hz, 5A |

| Cathode gas Argon Nitrogen Hydrogen Helium Anode gas Argon Nitrogen |

250 scfh @ 85 psi (120 l/min @ 5.8 bar) 250 scfh @ 85 psi (120 l/min @ 5.8 bar) 50 scfh @ 100 psi (24 l/min @ 6.8 bar) 150 scfh @ 100 psi (70 l/min @ 6.8 bar)50 scfh @ 85 psi (24 l/min @ 5.8 bar) 50 scfh @ 85 psi (24 l/min @ 5.8 bar) |

| Carrier 1 – Argon Carrier 2 – Argon |

50 scfh @ 85 psi (24 l/min @ 5.8 bar) 50 scfh @ 85 psi (24 l/min @ 5.8 bar) |

| Chiller | 15 tons (55 kW), Model 3 torch 20 tons (70 kW), Model 5 torch |

| Water flow and pressure | 12 gpm @ 175psi (45 l/min @ 12 bar) |

| Power supply, 100kW | 380/480V, 3-phase |

| Operator interface | 15” touch screen |

| Powder feeder | Uniquecoat G4 preferred |

Contact us for pricing, availability and more information.